A huge number of automatic washing machines have a drum made of stainless steel. Their only difference is the different surface of the drum. Washing machines with a honeycomb drum are designed to provide gentle and delicate cleaning of fabrics from impurities, while not compromising the quality of the fabric.

A huge number of automatic washing machines have a drum made of stainless steel. Their only difference is the different surface of the drum. Washing machines with a honeycomb drum are designed to provide gentle and delicate cleaning of fabrics from impurities, while not compromising the quality of the fabric.

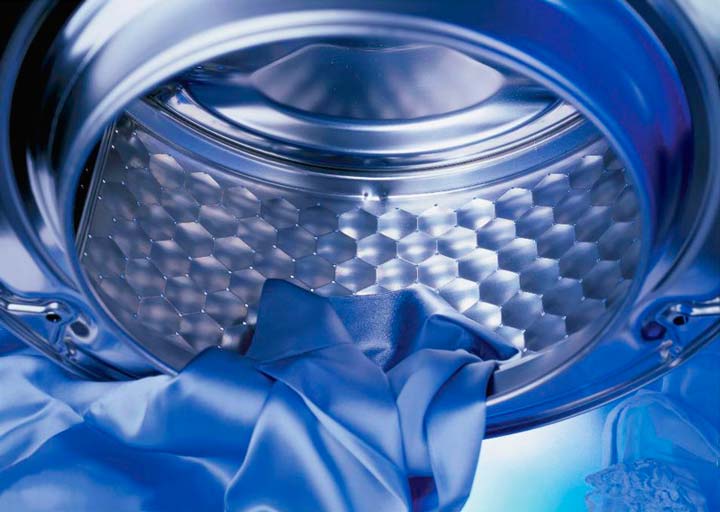

Design features of the honeycomb drum of a washing machine

This technology was patented by the German manufacturer Miele, which produces high (premium) class appliances.

This technology was patented by the German manufacturer Miele, which produces high (premium) class appliances.

On the surface, which is located inside the drum, there are slightly convex hexagons with angles of 120 degrees.

You can say that in appearance they resemble a bee honeycomb.

In order for the water to circulate in the tank, on the edges of these regular shaped hexagons there are very small holes, which are much smaller than in a standard washing machine.

The main differences from a standard drum

Conventional drums Provide holes to circulate water all around the perimeter and area. Their diameter is such that when spinning at high speeds, the fabric is drawn into them due to centrifugal force. In addition, the material is subjected to friction against the walls during washing. This has a rather bad effect on the further appearance of things: they stop looking like new, and unloved lint appears on the clothes.

Conventional drums Provide holes to circulate water all around the perimeter and area. Their diameter is such that when spinning at high speeds, the fabric is drawn into them due to centrifugal force. In addition, the material is subjected to friction against the walls during washing. This has a rather bad effect on the further appearance of things: they stop looking like new, and unloved lint appears on the clothes.

This reduces wear and tear and deformation of the fabrics even when spin at high speed. Such a surface even appears softer and smoother, and the holes are much smaller in diameter than in standard counterparts. In addition, this structure prevents different small objects in the tank and the drain system during the washing process (buttons, coins, bra bones, etc.).

This reduces wear and tear and deformation of the fabrics even when spin at high speed. Such a surface even appears softer and smoother, and the holes are much smaller in diameter than in standard counterparts. In addition, this structure prevents different small objects in the tank and the drain system during the washing process (buttons, coins, bra bones, etc.).

Pros and cons of the honeycomb drum of the washing machine

The honeycomb drum has many advantages. Here are some of them:

Gentle on the fabric. Water mixed with dissolved detergent during the washing process remains in the small cells and creates a thin invisible film. Due to this, the process of friction and deterioration of things is minimized, so the washed material is not subject to early wear and tear.

Gentle on the fabric. Water mixed with dissolved detergent during the washing process remains in the small cells and creates a thin invisible film. Due to this, the process of friction and deterioration of things is minimized, so the washed material is not subject to early wear and tear. Durability and strength. The drum of this type is a cast construction, which is made by rolling. There are no welded parts in it, due to which the service life of the washing machine is significantly increased.

Durability and strength. The drum of this type is a cast construction, which is made by rolling. There are no welded parts in it, due to which the service life of the washing machine is significantly increased.- Efficiency. Miele's team of experts tested their unit and found that cellular drums consume water and electrical energy much more economically than conventional machines.

Many consumers do not agree and are not going to overpay, so give preference to cheaper devices, or analog devices at a lower cost. In any case, the superiority of this machine no one undertakes to argue.

Washing machine Diamond with honeycomb drum

The company Samsung also positions its machines as devices with honeycomb drums, but they have a slightly different structure. And the name of this model - "Diamond" - in translation means "diamond".

The company Samsung also positions its machines as devices with honeycomb drums, but they have a slightly different structure. And the name of this model - "Diamond" - in translation means "diamond".

The drum is made of convex parts as in Miele machines, but in this case they are quadrangles, on the tops of each of which there are small diameter holes.

In the drums of the new technology called Diamond+, the holes are transferred to the concave part, which has become more similar to the Miele design. The edges of these "honeycombs" have the shape of light waves for smoother sliding. Compared to conventional machines, this drum also treats your clothes more gently, protecting them from lint and other damage.

In the drums of the new technology called Diamond+, the holes are transferred to the concave part, which has become more similar to the Miele design. The edges of these "honeycombs" have the shape of light waves for smoother sliding. Compared to conventional machines, this drum also treats your clothes more gently, protecting them from lint and other damage.