When the washing machine breaks down, and it is no longer feasible to repair it, then there is a need to buy a new one. Do not rush to throw away the old washing machine. If engine is in working orderWhy should it go to waste? From it you can make a lot of useful things that will be useful to you at home. Let's see what you can make from the engine from an old washing machine.

When the washing machine breaks down, and it is no longer feasible to repair it, then there is a need to buy a new one. Do not rush to throw away the old washing machine. If engine is in working orderWhy should it go to waste? From it you can make a lot of useful things that will be useful to you at home. Let's see what you can make from the engine from an old washing machine.

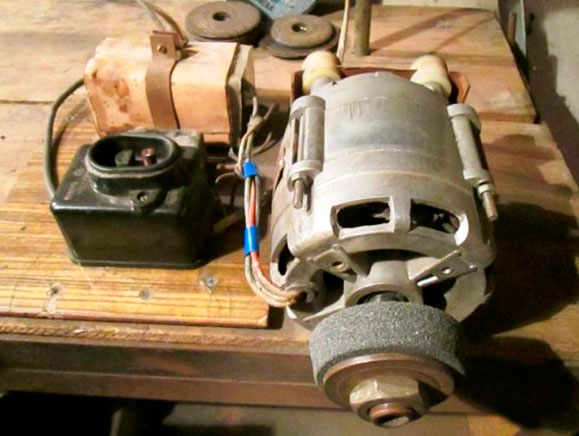

An electric emery from a washing machine motor

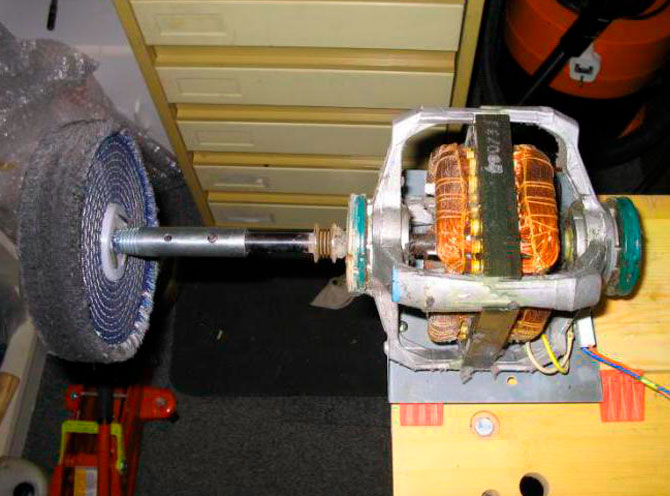

One of the options for using the engine from the washing machine is to make an electric emery. This device will be very necessary in the household. Thanks to him you can quickly sharpen a knife, drill bit, scissors and any other cutting tools. Of course, the task is not one of the easy ones, but with a skillful approach everything can be done quickly enough.

The first and most important task - is to attach the sharpening stone to the motor itself, or rather to the motor shaft. The problem is that the main diameter of the hole in the sharpening stone and the diameter of the washing machine motor shaft are completely different. This problem is solved. It is necessary to prepare a special flange, which will have two different sides. On one side will be the necessary threads to securely fasten the emery wheel, and on the other side the motor shaft will be pressed. You will need a small piece of steel pipe with a diameter of 32 millimeters to make the flange.

The process of making the flange:

- We take the necessary pipe (at 32 millimeters). The length of the pipe should not exceed 20 centimeters.

- Now you need to cut a thread on one end of the pipe. For reliable fixation of the flange on the shaft, it is necessary that the thickness of the emery wheel is half the length of the thread. It is very important to consider the direction of the thread. It must be cut in the opposite direction of rotation of the motor shaft. Otherwise, the sharpening stone will simply fly off the shaft as it rotates.

- The other end of the shaft should be heated with a blowtorch and pressed onto the shaft. Once cooled, the tube will be securely attached to the shaft. You can weld the pipe to the shaft for a stronger connection. If there is no welding, you can just drill a hole and connect it with a bolt and nut.

- Now you need to find three nuts and two washers of the right size. On the end of the pipe with threads screw one nut to the stop, put the appropriate washer, then an emery wheel, then another washer and screw it all with the second nut. Screw it all in tight, and at the end also secure it with the third nut.

The main task is done, now it is necessary to fix the engine securely. The stand for the mount is made depending on the presence of mounting holes on the engine. After the stand is made, we fix the engine on the workbench. The motor brackets on some washing machines are great for mounting to the workbench.

Connecting it to the power supply

After the motor with the emery is fixed on the workbench, it is necessary to connect it to the power supply.

- Using a special multimeter you need to find the working terminal. To do this, you need to check the resistance of each lead. The resistance at the working lead should be about 12 ohms.

- Connect the work lead to the mains.

- To start the sandpaper you need a special starter. If it is not available, you can start the sandpaper by hand, twisting the sandpaper stone strongly in the direction of rotation.

This concludes the process of making an electric sandpaper. The device is ready to work.

Making a lawn mower from a washing machine motor

Making a lawnmower is another option for the competent use of the engine from a washing machine. This device is very useful to those who have cottage and household plots. Making a lawnmower does not require a lot of materials, all the components can be found in the shed and garage.

Making a lawnmower is another option for the competent use of the engine from a washing machine. This device is very useful to those who have cottage and household plots. Making a lawnmower does not require a lot of materials, all the components can be found in the shed and garage.

The manufacturing process

- The first thing you need to get the chassis, with which it will move. For this purpose, the wheels from any cart or baby carriage will do.

- A specially prepared metal platform must be installed on the chassis. The platform can be made either of metal sheet and square angle. A special frame is made from the angle. Racks for the wheels are already welded to it.

- For a handle you can adapt the pipe is not too large in diameter. The height of the handle is chosen according to the height of the person who will operate it. The handle is welded to the frame with a gas or electric arc welding.

- Now you need to prepare a hole in the platform, so that the motor shaft can freely pass through it.

- Next, in the front you must place the grate. The grille is screwed on with the help of screws. The grille must have special gaps. 2 centimeters at the top and 1 centimeter at the bottom.

- The motor is attached to the platform so that the shaft goes through a specially prepared hole. The cutting tool (knives) should be attached to the end of the shaft by welding or pressing.

- To protect the engine from grass entering it, you need to cover it with a protective cover. However, it is worth bearing in mind that the engine can get hot and needs to be cooled. Therefore, the protective cover must have small openings in it.

- Now connect the power cable. As in the case of making the emery, you need to find the working lead with the help of a multimeter. The cable is connected to it. A cut with a plug and a special switch must be brought to the handle of the lawnmower.

This completes the process of making a lawnmower. To prevent accidental electrocution, it is best to rubberize the handles. Now the device is ready to work.

Making a lawn mower from a washing machine engine

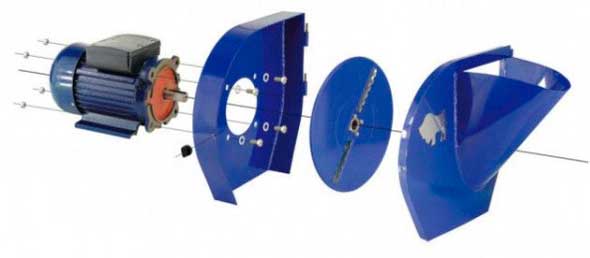

From the engine of a washing machine, you can also construct a feed cutter. This device will perfectly cut into small pieces a variety of fruits and vegetables of large size. Very useful thing in the economy.

Technology of making a feed cutter

- To make the feeder you will also need a drum from a washing machine. In its back part you will need to make a hole according to the diameter of the motor shaft.

- On the edges of the drum you need to make four holes. In these places will be attached bolts. And in one wall a large hole is made. It is through it that the finished raw material will fall out.

- The cutting element should be installed on the end of the motor shaft with the help of several bolts. The cutting element should consist of two blades. The lower blade should be with slightly bent ends.

- The whole resulting construction should be mounted on a support, which is made in the form of a stool with four legs.

- The drum should be closed with a lid from above, otherwise the materials will fly out of the drum during the grinding.

- As for the power supply, everything is the same as with the previous modifications. We find the working output and connect the power cable to it.

The chopper is ready to work. Thanks to such a device in just one hour can be processed up to 100 kilograms of raw materials of different cities.

Making a concrete mixer from a washing machine engine

If you have a construction project, then do not rush to throw away your old washing machine. From it you can make a full-fledged concrete mixer, which will greatly facilitate your construction process.

The process of doing the work of making a concrete mixer

- To begin with, you need to make a stable base, on which the device will be located. You can make it from a wooden bar 150 by 150. The bars are fastened using self-tapping screws. The base can be made of metal channels or corners. The base of metal is more stable and reliable.

- Shaft of the motor and the shaft of the container itself should be in one plane. With this calculation you need to make on the frame special shelves for fixing the motor.

- Next, install the gearbox. The pulley of the gearbox and the motor must be in the same plane. If this condition is not met, the motor will experience high overloads and will soon stop working.

- The tank of the same washing machine can be used as a mixing tank. A shaft is installed in the tank and special paddles for battering are attached to it. It is very important to observe the symmetry of the blades. They should be clearly opposite each other.

- Now connect the wiring, make the start and stop buttons. Pull the belts on the pulleys.

- To protect the gearbox and engine from the concrete mixture, it will be better to cover them with protective covers.

Making a generator out of a washing machine engine

From the engine of a washing machine you can make a generator for 12 V. To make it does not require a lot of work and many additional materials. All you need is 32 magnets of special size (20 x 10 x 5 millimeters).

The whole remodeling process is to remove the core layer and install special magnets. There are four poles on the rotor, and eight magnets are installed on each pole. On a lathe it is necessary to remove a small layer of the core and install the magnets in these recesses. Then the poles must be filled with epoxy, wrapped in paper beforehand. Now you need to install the new bearings. Find the working winding, and cut off the old wires. The generator is ready to go.

If you have imagination, working hands and the necessary knowledge, you can assemble other devices and devices for various purposes on the basis of the above examples. All the basic principles are outlined in the examples above. The analogy of production in most cases will be the same, except for the characteristic nuances.