Using modern appliances in our homes significantly increases the quality of life.

Using modern appliances in our homes significantly increases the quality of life.

It is almost impossible to imagine our existence without a washing machine. It is so ingrained in our lives that it has become an integral part of it.

Perhaps this is the most popular appliances that can: minimize manual labor, perform many operations, integrate into home management system, have a beautiful, designer look.

The stage of preparation for the installation and connection of the washing machine

The owner of the future washing machine is guided primarily by personal preferences, technical characteristics and financial capabilities. When in the house appears this miracle equipment, the first question that puzzles its owner: what does the independent connection of the washing machine and how to do it?

The owner of the future washing machine is guided primarily by personal preferences, technical characteristics and financial capabilities. When in the house appears this miracle equipment, the first question that puzzles its owner: what does the independent connection of the washing machine and how to do it?

Before buying a washing machine and bringing it to the house, it is advisable to already decide on the place of its installation. There are many models of different depths and sizes.

Although, in principle, if you are not going to embed the machine in a nightstand or in a separately designed and allocated space, you can think about the place of installation after bringing the helper home. The washing machine is standardly located in the bathroom, kitchen, hallway or pantry.

What requirements must be taken into account in this case?

- An even floor.

- Proximity of water supply, sewerage and electrical outlet.

- Convenient operation.

- Aesthetics.

Next, the dismantling of transporting parts is carried out: bolts, bars, brackets. Bolts fix the tank, which when unscrewing them should hang on the springs.

Next, the dismantling of transporting parts is carried out: bolts, bars, brackets. Bolts fix the tank, which when unscrewing them should hang on the springs.

This is a mandatory moment, otherwise the operation in their presence will cause malfunction of the equipment. The empty holes from the bolts are closed with plugs, usually included in the kit.

Brackets secure the power cord and water drain hose. Bars are placed between the tank and the body.

The next point in this step is to prepare the flooring for the machine. It must be durable, understandably horizontal and resistant to harsh conditions.

The next point in this step is to prepare the flooring for the machine. It must be durable, understandably horizontal and resistant to harsh conditions.

If the characteristics of the living space does not meet the requirements, you will need to take measures to ensure them. That is, you may need to lay a cement-sand screed on the floor or use other methods to strengthen the floor base.

Installing the washing machine

After the preparatory stage and unpacking the machine, it can be installed. You will need a level or plumb to set the machine strictly level with a tolerable angle of deviation of 2 degrees.

After the preparatory stage and unpacking the machine, it can be installed. You will need a level or plumb to set the machine strictly level with a tolerable angle of deviation of 2 degrees.

Check by the top cover. Adjust the angle of inclination by screwing in the support legs of the washing machine or on the contrary unscrewing them.

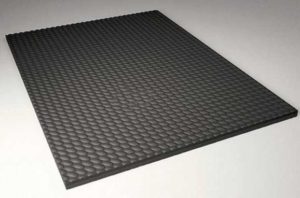

To put foreign objects under the machine is forbidden, as at vibration there is a great probability of their jumping out. If the appliance is installed on tiles or other slippery surfaces, it is advisable to purchase a rubber mat - an excellent shock absorber.

To put foreign objects under the machine is forbidden, as at vibration there is a great probability of their jumping out. If the appliance is installed on tiles or other slippery surfaces, it is advisable to purchase a rubber mat - an excellent shock absorber.

After adjusting the feet, they should be secured with a locknut that is screwed counterclockwise.

What else do I need to know before connecting the machine?

- The most stable position of the machine is ensured when the feet are fully screwed in. However, this is only possible when the surface is perfectly flat.

- Check the stability of the appliance You can check the stability of the machine by swinging it diagonally. If it swings, it means either it is installed incorrectly or, if the rigidity of the body does not allow it, the amplitude of the swing for different diagonals should be the same.

- If installation on a flat surface is not possible, and the option with a sloping floor is considered, then you will need fasteners for fixation.

Connecting the washing machine to the water supply

Some also use hot water in order to save electricity, but the question is debatable, because you have to waste hot water.

Some also use hot water in order to save electricity, but the question is debatable, because you have to waste hot water.

To make the water connection to the washing machine will need a water hose. It usually comes with the washing machine. The hose to connect the washing machine is provided with fittings, but there is one nuance, which is that the length of the standard hose (70-80 cm) is usually not enough.

In this regard, you can buy the right length of rubber hose in the store or use a fixed connection.

In the first option, everything is simple - the machine is connected to the inlet spigot of the equipment and the water intake point.

There are some points for this:

- The water hose must pass in a place inaccessible to mechanical damage, it is better if it is hidden;

- the hose must lie freely, not stretched, otherwise it can be deformed;

- the quality of the rubber hose affects the reliability of use, as well as tightness during operation of the washing machine.

If we consider the second case of connecting the washing machine, the water is carried to the machine by means of laying stationary communications. Here you will need pipes (metal) and plastic systems.

The use of steel pipes is impractical and not practical, as frequent clogging with rust of the pipe itself and parts of the unit will quickly put the washing machine out of operation.

When using all-metal pipes, it is necessary to take into account the fact that the direct connection of the washing machine automatic will not provide high tightness, so the use of a hose-adapter can be considered a necessity, in order to avoid leaks.

There is a way to connect the washing machine through a faucet. In this case, you will need a long hose. The inconvenience is that before each wash you have to unscrew the faucet and replace it with a water inlet hose. This option is rather temporary.

There is a way to connect the washing machine through a faucet. In this case, you will need a long hose. The inconvenience is that before each wash you have to unscrew the faucet and replace it with a water inlet hose. This option is rather temporary.

There are models of washing machines, which are equipped with an AQUA-stop. The meaning of the work is that drain hoseHaving at the end of the electromagnetic valves, which shut off the water when the machine is turned off.

The main points, without knowledge of which the connection of the washing machine to the water supply will be poor quality:

Water supply points should be equipped with ready-made outlets in the direction of the faucet or flushing barrel. Pipelines are connected through tees or individual nipples and fittings.

Water supply points should be equipped with ready-made outlets in the direction of the faucet or flushing barrel. Pipelines are connected through tees or individual nipples and fittings.- Use a ball valve that can turn off the user at the right time.

- Try to decide on a filtering system. It is possible to use mechanical or magnetic systems that purify water, which will significantly prolong the life of the technique

Connection to the sewage system

Connecting the drain of the washing machine to the sewer does not seem to be such a difficult process. Two ways are possible:

When the drain hose is fixed to the tub, for example. The hose is simply screwed to the spigot of the machine, and the other end is lowered into the bathtub. To avoid flooding of the room, the hose is securely attached to the back of the machine no higher than 80 cm. Take into account that corrugated hoses are prone to fast clogging, so the minimum bend radius should be 50 cm, and the maximum - 85 cm. For this purpose, clamps are used to monitor and control the correct position of the hose.

When the drain hose is fixed to the tub, for example. The hose is simply screwed to the spigot of the machine, and the other end is lowered into the bathtub. To avoid flooding of the room, the hose is securely attached to the back of the machine no higher than 80 cm. Take into account that corrugated hoses are prone to fast clogging, so the minimum bend radius should be 50 cm, and the maximum - 85 cm. For this purpose, clamps are used to monitor and control the correct position of the hose. Connecting the drain of the washing machine directly to the sewer. A more complicated option. It should be taken into account that the drain hose should not be too long, otherwise it causes an increased load on the pump and can damage it. In order to avoid penetration into the machine smell and impurities from the sewer system, siphons are used to prevent this. Or the drain hose is fixed so that an air lock is formed in it, taking into account the minimum distance from the floor to the bend of 0.5 meters.

Connecting the drain of the washing machine directly to the sewer. A more complicated option. It should be taken into account that the drain hose should not be too long, otherwise it causes an increased load on the pump and can damage it. In order to avoid penetration into the machine smell and impurities from the sewer system, siphons are used to prevent this. Or the drain hose is fixed so that an air lock is formed in it, taking into account the minimum distance from the floor to the bend of 0.5 meters.

Connecting the washing machine to the mains

The washing machine is in constant contact with water, which requires compliance with the following points:

Individual routing of power cables for the washing machine from the switchboard is recommended. Save the integrity of the interior will help boxes made of plastic.

Individual routing of power cables for the washing machine from the switchboard is recommended. Save the integrity of the interior will help boxes made of plastic.- Ensuring electrical protection with the help of special devices - circuit breakers, protective disconnection device. It will turn off the voltage if there is a contact between a person and a wire. Such a device will protect the machine from mechanical impact, moisture and problems with the insulation. It is usually selected one stage higher in current than the rating of the unit. The leakage current is also taken into account. If the machine is connected to an individual line, this figure is 10 mA.

- Use a cable with three conductors and a cross section of at least 1.5 sq.mm.

Outlets must be grounded, with the wire going into the panelboard to the grounding bus with a cross section of 3 mm. It is forbidden to connect this conductor to the water and heating system in order to exclude the possibility of equipment damage.

Outlets must be grounded, with the wire going into the panelboard to the grounding bus with a cross section of 3 mm. It is forbidden to connect this conductor to the water and heating system in order to exclude the possibility of equipment damage.

When installing the socket, you should think about the fact that the wet environment is not desirable and it may be necessary to use adjacent rooms. You should also pay attention to the degree of electrical safety of outlets, it is desirable to purchase with a ceramic base and with a protective cover.

Be sure to take into account what voltage it is designed for. Connect the washing machine through the adapter is not recommended because of the heat of the contacts and the failure of the unit.

Functional testing

After preparation, installation and connection, a test run of the equipment is performed. For this purpose, the water and power supply is opened.

Check leak tightness and other possible defects.

Check leak tightness and other possible defects.

After this, the first wash without laundry is started on the program with maximum water heating temperature.

This is done to remove the factory grease.

After a successful test, you can consider the machine ready for use.