The washing machine lock is not the most complex device, but without it, washing is impossible. It is needed to lock and seal the hatch during washing, rinsing and laundry spin.

The washing machine lock is not the most complex device, but without it, washing is impossible. It is needed to lock and seal the hatch during washing, rinsing and laundry spin.

This device is designed to provide reliable automatic protection against unintentional opening of the door, and in case of breakage, it stops the washing program. Door lock device in case of failure and wear and tear requires repair or replacement of the lock on the washing machine.

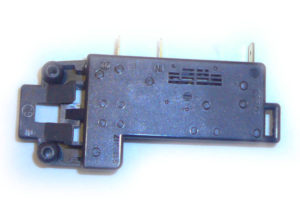

How the washing machine lock is designed and how it works

Washing machines from different manufacturers are equipped with One of two types of locking devices for locking the hatch:

Washing machines from different manufacturers are equipped with One of two types of locking devices for locking the hatch:

- Electromagnetic. Can't boast of reliability and efficiency.

- With bimetallic elements..

Common on modern machines. More popular. The principle of operation of such a lock is based on the close cooperation of three elements:

Common on modern machines. More popular. The principle of operation of such a lock is based on the close cooperation of three elements:

- the latch;

- thermocouple;

- bimetallic plate.

When a command is received from the appliance control module, the washing machine hatch locking device receives a current charge to the thermocouple. The thermocouple heats up instantly, which causes the bimetallic plate to heat up, which becomes even longer and expands. In this state, it presses the detent and it immediately reacts and locks the washing machine. Until the plate cools down, the door will be blocked.

When the power supply is cut off, the thermocouple does not receive heat and the plate cools, causing the door to unlock. If the locking device or the triac responsible for its operation in the control module is broken, when the voltage is constantly applied to the lock, it will not be able to open until the machine is de-energized. If the contact of the heating element is broken or broken, then the heating will not happen at all, and then the hatch can not close.

How to Test a Washing Machine Lock

To determine the functionality of the washing machine lock device, you will need a tester - a multimeter. Before checking the lock is removed. To do this:

- open the hatch in the washing machine;

- locate the wire ring;

- remove the ring with a screwdriver;

- adjust cuff so that the lock can be removed;

- unscrew the bolts that are attached to the lock and pull it out.

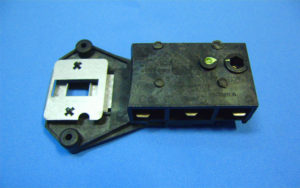

It is necessary to find out which is the phase, which is the neutral and which is the common contact.

It is necessary to find out which is the phase, which is the neutral and which is the common contact.

Many companies make devices with a bimetal plate and the position of the contacts often differs. It is very difficult to use a multimeter and make a check without studying the circuit diagram.

Let's assume that the contacts are understood. Let's proceed with the test.

- Т

The unit's umbler is switched to test mode.

The unit's umbler is switched to test mode. - One probe is attached to the neutral contact and the other to the phase contact.

- If the tester shows a three-digit number, then all is good.

- Now the probes are set on the neutral and common contacts.

- If the gauge shows 0 or 1 - the blocker is obviously defective.

In the case if the test did not find the breakage, but at the same time the problem is clearly there, then the cause is probably not in the electrics, but in the mechanics.

If the problem is mechanical, then the door of the washing machine may remain locked for many hours after it is de-energized. When the display shows error code problems with the hatch locking device when washing, the problem is there. Also, if the washing machine does not want to lock the hatch, either the lock itself or the control module is broken. You can find this out with a multimeter or by replacing the device with a new one.

If the problem is mechanical, then the door of the washing machine may remain locked for many hours after it is de-energized. When the display shows error code problems with the hatch locking device when washing, the problem is there. Also, if the washing machine does not want to lock the hatch, either the lock itself or the control module is broken. You can find this out with a multimeter or by replacing the device with a new one.