If you think that the smooth operation of your washing machine depends only on its parts, installation and assembly, you're wrong. It also depends on proper transportation. The drum - is the most exposed part of your washer in transit. It is mounted on strong spring shock absorbers, so it can move almost unhindered inside the washing machine. During transportation, the drum can accidentally damage the inside of the machine. To prevent such an unpleasant situation were foreseen transportation bolts in the washing machine.

If you think that the smooth operation of your washing machine depends only on its parts, installation and assembly, you're wrong. It also depends on proper transportation. The drum - is the most exposed part of your washer in transit. It is mounted on strong spring shock absorbers, so it can move almost unhindered inside the washing machine. During transportation, the drum can accidentally damage the inside of the machine. To prevent such an unpleasant situation were foreseen transportation bolts in the washing machine.

Every person who at least once purchased such appliances, most likely met with similar fasteners. The most important thing is not to forget to remove them before using them. Otherwise, it can lead to a breakdown of a brand new washing machine. In this article, you will learn why you need transport bolts in the washing machine, how to properly transport this technique and how to remove them.

Every person who at least once purchased such appliances, most likely met with similar fasteners. The most important thing is not to forget to remove them before using them. Otherwise, it can lead to a breakdown of a brand new washing machine. In this article, you will learn why you need transport bolts in the washing machine, how to properly transport this technique and how to remove them.

Fixing devices. What are they for?

In order to minimize the risk in transit, they are installed at the factory, and in various tilts during transportation, the internal parts do not contact each other, because the bolts hold the tank in the same position.

In order to minimize the risk in transit, they are installed at the factory, and in various tilts during transportation, the internal parts do not contact each other, because the bolts hold the tank in the same position.

This keeps the shock absorbers and bearings also remain intact.

These are very important elements of the washing machine, because they reduce the amount of vibrations when washing and wringing.

How to remove the transport bolts on a washing machine

If this advice is neglected, then, in the end, because of the improper operation of the entire mechanism, the washing machine will fail. Also, no service center will undertake to repair or replace the appliance free of charge if the shipping bolts prove to be the cause of the breakdown.

If this advice is neglected, then, in the end, because of the improper operation of the entire mechanism, the washing machine will fail. Also, no service center will undertake to repair or replace the appliance free of charge if the shipping bolts prove to be the cause of the breakdown.

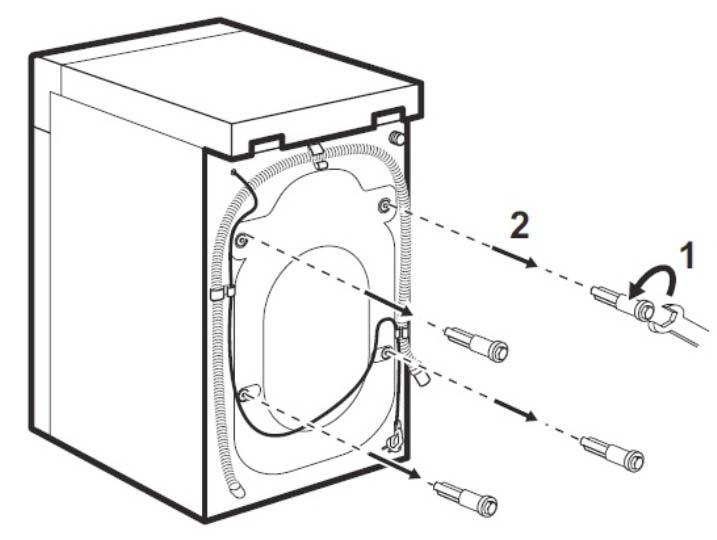

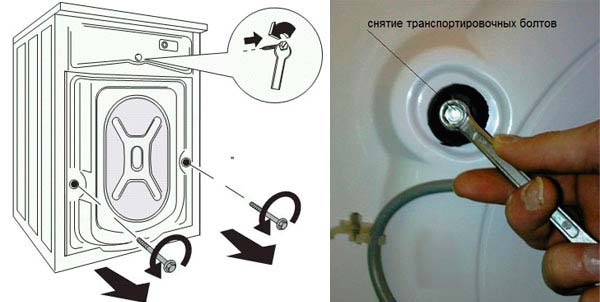

Therefore, as a rule, it is not difficult to find them. Usually there are no more than four of these bolts.

In some companies, they are in the form of small iron pins and can be located, for example, on the top wall.

In some companies, they are in the form of small iron pins and can be located, for example, on the top wall.

In order to be able to start the operation of the washing machineThey just need to be unscrewed.

A universal wrench is quite suitable for this.

The required size, as a rule, ranges from ten to fourteen millimeters, depending on the brand of manufacturer. In the kit of some companies (eg LG), includes a suitable size wrench to remove the mounting screws, together with the drain hose and other standard parts of the washing machine.

The required size, as a rule, ranges from ten to fourteen millimeters, depending on the brand of manufacturer. In the kit of some companies (eg LG), includes a suitable size wrench to remove the mounting screws, together with the drain hose and other standard parts of the washing machine.

If you don't have a wrench handy, you can try using pliers. And if the manufacturer used metal pins as fasteners, it is best to unscrew them using pliers. To get the shipping bolts or pins, it is enough to twist them a quarter turn and then pull them all the way out of the body of the device by hand.

If you don't have a wrench handy, you can try using pliers. And if the manufacturer used metal pins as fasteners, it is best to unscrew them using pliers. To get the shipping bolts or pins, it is enough to twist them a quarter turn and then pull them all the way out of the body of the device by hand.

Tips for transporting an automatic washing machine

As practice shows, you should not throw away the shipping bolts immediately after removing them, as no one knows what the future holds.

You may have to change your abode and move to a new house. That's when the shipping bolts will need to be put back in place to reduce the risk of possible damage in transit.

You may have to change your abode and move to a new house. That's when the shipping bolts will need to be put back in place to reduce the risk of possible damage in transit.

The decorative plugs can be removed very easily with manicure scissors or a regular knife. The fixing bolts can be screwed in without any foreign objects, so the whole procedure will not take you much time. This way you can increase the operating time of your machine and do not have to fear for it during transport.

Conclusion

People have come up with many features to protect the unit during transport and maintenance, the main ones being the shipping bolts. They preserve the spring suspension system. Before the machine for the first time they must be removed, and if necessary, put them back in.

This is a useful article, because when we bought a hotpoint washing machine, we completely forgot to remove the fasteners. Actually because of that at first the washing machine was unnaturally noisy.