The washing machine draws and drains water thanks to the most important element - the pump. With prolonged use, it can break down (physical wear and tear), which is quite common, which is why the pump is considered the weak point of modern washing machines.

The washing machine draws and drains water thanks to the most important element - the pump. With prolonged use, it can break down (physical wear and tear), which is quite common, which is why the pump is considered the weak point of modern washing machines.

Signs of a washing machine pump breakage

If there are problems with the pump, the machine may:

- Does not respond to the set program;

- emit humming noises When filling or draining water;

- Fill the drum with less water than it is supposed to be filled;

- during the process of water intake, it is possible to turn off the equipment completely.

To to diagnose and, if necessary, to repair the pump of the machine or to replace it:

to listen to how the machine works In order to identify extraneous sounds. If the machine makes a lot of noise when draining, it means there is water in the pump or some of its parts are deformed;

to listen to how the machine works In order to identify extraneous sounds. If the machine makes a lot of noise when draining, it means there is water in the pump or some of its parts are deformed;- open panel to remove clogs in the drain filter.. All small and foreign objects are here - hair, threads, buttons, seeds, etc;

- clean the drain hose. Even if it does not look damaged, you should remove it and rinse under hot water;

check the impellerCheck that the impeller is working correctly and may be stuck. It is located behind drain filterThe fan blades will be visible and need to be rotated. The impeller blades will be visible and must be rotated. The rotation should not be too light. If there is any debris such as brassiere knuckles, coins, threads and hair, this should be removed;

check the impellerCheck that the impeller is working correctly and may be stuck. It is located behind drain filterThe fan blades will be visible and need to be rotated. The impeller blades will be visible and must be rotated. The rotation should not be too light. If there is any debris such as brassiere knuckles, coins, threads and hair, this should be removed;- Check the integrity of the contacts and the functioning of the sensors going to the pump.

If in the process of diagnosis the cause of problems in the washing machine was determined by the pump, then it will be necessary to examine it. To get to it will need standard tools.

The causes of pump failure

The pump broke down due to a malfunction of the motor, as a result of which there is no voltage to the pump.

The pump broke down due to a malfunction of the motor, as a result of which there is no voltage to the pump.- The seal (rubber or plastic) is damaged by limescale and dirt that settles on the impeller.

- Incorrect connection of the pump or failure of the water level sensor causes permanent pump operation.

- The pump will not be able to drain due to clogged filter.

- Small foreign objects destroy the impeller. This is easy to diagnose. When you start the pump, the machine makes a whooshing sound.

Where is the pump

Washing Machine Models Candy, LG, Whirpool, Ariston, Beko, Samsung have a pump that is located at the bottom. To get to it, the washing machine is laid on its side and the bottom panel is removed. The cochlea with the filter is attached with screws, which are unscrewed and the necessary part is in your hands.

Washing Machine Models Candy, LG, Whirpool, Ariston, Beko, Samsung have a pump that is located at the bottom. To get to it, the washing machine is laid on its side and the bottom panel is removed. The cochlea with the filter is attached with screws, which are unscrewed and the necessary part is in your hands.

If we talk about the models Zanussi, Electrolux, the pump is located behind the back cover, which you will need to remove.

The most difficult models in terms of disassembly are Bosch, AEG, Siemens. They will have to dismantle the entire front panel.

Repair of the washing machine pump with their own hands

During heavy loads, the pump is protected by fuses, which are located on the winding of the part and are tripped. When the temperature normalizes, the contacts are restored.

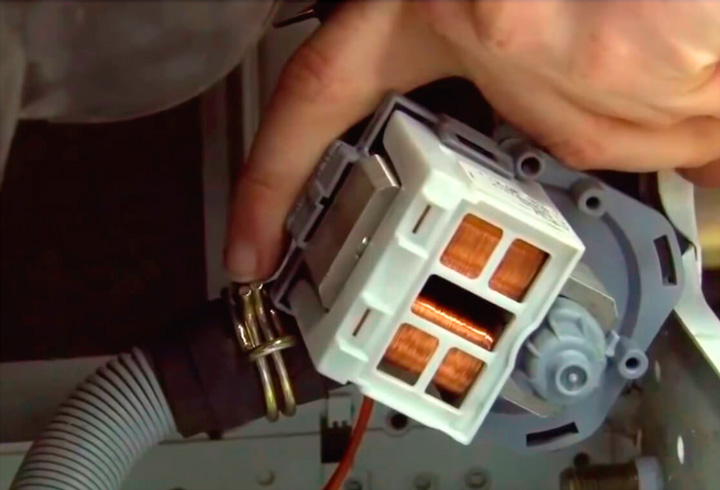

To begin with disconnect the pump from the volute. Generally, there are two types of attachment: simply with screws and screwless (you only need to turn the pump counterclockwise). At this stage you can find out if the impeller is rotating on the shaft. Normally it should rotate with small delays, so-called jumps. This is due to the action of the magnet rotating in the coil. If it is difficult to turn and there is no debris, then you will have to completely disassemble the part and see if it is possible to repair the impeller of the washing machine pump.

To begin with disconnect the pump from the volute. Generally, there are two types of attachment: simply with screws and screwless (you only need to turn the pump counterclockwise). At this stage you can find out if the impeller is rotating on the shaft. Normally it should rotate with small delays, so-called jumps. This is due to the action of the magnet rotating in the coil. If it is difficult to turn and there is no debris, then you will have to completely disassemble the part and see if it is possible to repair the impeller of the washing machine pump.

There is a latch on the motor housing on both sides, which you need to unhook with a screwdriver. This is if your machine has a collapsible motor, but there are non-disassembled types. At first glance it is impossible to disassemble it, but if you know some nuances, you can.

There is a latch on the motor housing on both sides, which you need to unhook with a screwdriver. This is if your machine has a collapsible motor, but there are non-disassembled types. At first glance it is impossible to disassemble it, but if you know some nuances, you can.

A construction hair dryer to warm the long part of the part, the so-called shank at a low temperature. After heating the shank, the cross with the magnet is removed from the body. Usually dirt accumulates on the magnet and in the place where it was pulled out. After cleaning, the magnet itself is removed. Next you will see the bearing, which is also cleaned and lubricated. After these procedures, the part is put back together. Under the blades is a ring, which should fit tightly in place. It may be necessary to replace the oil seal.

A construction hair dryer to warm the long part of the part, the so-called shank at a low temperature. After heating the shank, the cross with the magnet is removed from the body. Usually dirt accumulates on the magnet and in the place where it was pulled out. After cleaning, the magnet itself is removed. Next you will see the bearing, which is also cleaned and lubricated. After these procedures, the part is put back together. Under the blades is a ring, which should fit tightly in place. It may be necessary to replace the oil seal.

Bearing Wear and Tear

Because of this, there is friction between the volute and impeller, which causes malfunction and repair of pumps of washing equipment. You can solve the problem by replacing bearings. In an emergency case, when there is no possibility to buy a new part, and the washing can not wait, will be saved only by shortening the blade by no more than 2 mm. This is done with a sharp knife.

After the repair, the housing is installed in the coil and secured. This ends the troubleshooting of the pump by your own efforts.

How to prevent pump failure

If you follow these recommendations, you can significantly prolong the life of the drain pump.

Always remove foreign objects from pockets before washing.

Always remove foreign objects from pockets before washing.- Use garment wash bags.

- For heavy, coarse dirt, clean clothes and also get rid of pet hair by hand before immersing in the machine.

- Install filters on the inlet of the fill tube.

- Carry out limescale prevention.

- When washing things with buckles, rivets, turn things inside out.