The washing machine has long been not a rarity and is a mandatory attribute of every home.

The washing machine has long been not a rarity and is a mandatory attribute of every home.

Always its breakdown is a nuisance, so there is a desire to quickly return the washing machine to work.

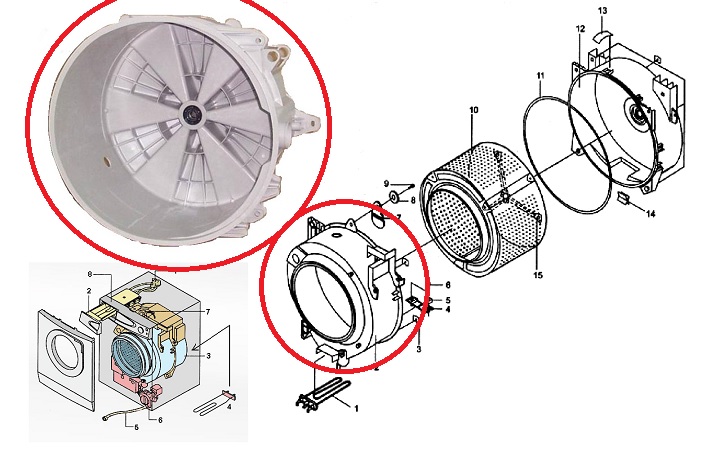

The tank of the washing machine - its main and main part.

In this article, let's look at how to fix the problem associated with the tank of the washing machine.

What is the tank of a washing machine

It is in the tank there are moving parts of washing machines and the drum, including.

The tank carries out the washing of laundry, despite the fact that it directly interacts only with the walls of the drum.

The tank carries out the washing of laundry, despite the fact that it directly interacts only with the walls of the drum.

It is the tank that receives the water and it seems that such a sturdy, but at the same time it does not seem to perform the main work of the mechanism can not break.

However, there is something in the tank that can fail. Repairing the tank of the washing machine is quite a labor-intensive job, and in order not to redo it, you will have to work to the best of your ability.

If you need to get to the heart of the machine, you will have to disassemble it completely, then take out the tank and disassemble it too. The last step of the job after repairing the washing machine tank – is to reassemble in the reverse order.

Types of tanks

- enameled,

- stainless steel and

- plastic.

Today it is rare to find an enameled tank.

Stainless tank - reliable and can serve for decades, but its production is quite costly. Therefore, this type is found in expensive models.

The plastic tank is in most modern machines. They are made simply, weigh little, heat water quickly.

Faults in the tank

What can break in the tank?

Bearings. A very inexpensive part, but it takes a lot of effort and time to replace it, risking serious damage to the shaft, pin and other parts. Bearings are located in the tank and are among the moving parts.

Bearings. A very inexpensive part, but it takes a lot of effort and time to replace it, risking serious damage to the shaft, pin and other parts. Bearings are located in the tank and are among the moving parts.- Drain hole at the tank.. Or rather, the drain valve, which usually breaks or gets clogged and requires cleaning.

- Shaft. Usually the problem with the shaft is a consequence of unrepaired bearing failure.

- Tank walls .. Also a consequence of improperly functioning bearings and shock absorbers, which cause the tank walls to deform under the centrifugal force of the drum.

How to Disassemble the Tank

Depending on the model of the washing machine, the tank can be:

- non-disassembled,

- collapsible.

Disassembling the tank needs a careful and painstaking approach.

Repair of the indestructible tank

Disassembly

Repair of the non-disassembled tank of the washing machine is much more difficult.

Before you start disassembling the part, you need to look at the body from all sides and find the place of the soldered seam. You will need it to drill a hole for the fasteners to reassemble the part.

Before you start disassembling the part, you need to look at the body from all sides and find the place of the soldered seam. You will need it to drill a hole for the fasteners to reassemble the part.- Armed with a drill and a thin drill bit, you need to drill 15-20 holes in a circle along the seam.

- Next, this seam must be sawed to get inside the tank. This is done with a hacksaw for metal. It takes a lot of time, you will need patience. The maximum depth when sawing the tank should not be more than 5 cm, otherwise you can cause irreparable damage to the walls of the tank.

After this step, the non-disassembled tank became demountable and consists of two parts - front and back.

After this step, the non-disassembled tank became demountable and consists of two parts - front and back.

The front one is an irregularly shaped plastic ring with a manhole and a rubber cuff in the middle.

The rear one consists of a drum with a driving mechanism, which we will remove. To do this we turn this part upside down and start to disassemble the shaft.- Be careful with the screw in the middle. In order to unscrew it you will need to put a metal rod on which you need to hit with a hammer. After these steps, the screw can be unscrewed with a screwdriver.

- Now it is the turn of the shaft. It is removed with 3 wooden blocks (1 small and 2 large). The tank is placed on the large bars and a hammer is used to hit the small bar, which is placed on the rod. Even though the rod looks sturdy, the blows must be of a certain strength - weak, stronger and even stronger so as not to damage the part. As a result, the drum should separate from the tank.

- It is possible not to dismantle the bearings, if there is no problem with them. A damaged tank may be to blame.

- But often the bearings or oil seals still have to be replaced, then you need a metal rod, with which you apply light blows with a hammer on the edges of the part. It is never advisable to tap on one edge to avoid drilling out the part. Both bearings should be replaced if they are defective.

After all the work is done the machine is reassembled in the reverse order.

Assembly

With what to glue the tank of the washing machine after repair?

With what to glue the tank of the washing machine after repair?

The sawed parts of the tank are lubricated with sealant and glued together.

You can use cold welding.

Bolts are inserted into the drilled holes and secured with nuts.

The size of the bolts will depend on the diameter of the holes you drilled.

What to do if the tank body is deformed?

First of all, you need to analyze the nature of the damage and the extent of the work.

If the tank is plastic

If the tank is plastic, it is possible that cracks have formed on it and they are the cause of water leakage.

If the tank is plastic, it is possible that cracks have formed on it and they are the cause of water leakage.

Option with soldering cracks immediately rejected, because it is - conditional repair of washing tanks, which will last very little time.

The best option - replacement with a new tank. The metal tank is more expensive than the plastic one.

If the tank is made of stainless steel

If you consider the repair of the stainless steel tank, then here the option of using welding is justified. Of course, it is better to trust an experienced welder to do everything neatly and quickly. After welding, you can paint the seam with water-resistant enamel to increase the life of the part.

Deformed repair

If the tank is warped, the repair is as follows:

- A hammer with a block of wood will be needed. If the damage is small without holes, no other tools are needed.

- The dent should be heated using, for example, a gas burner. The outside of the tank is heated.

- Hit with a hammer on the bar, not a dent, but a bulge, until the metal cools.

Drain Repair

If the malfunction is in the drain system, the plan of action is as follows:

- Check the drain for a clog. It may be necessary to remove water stone, for this purpose it is convenient to use sandpaper.

- The sealing rubber and the cuff also require a thorough inspection. It happens that the rubber becomes oaky and cracks, in which case the only way out is to replace it with a new one.

- The drain valve has contacts, it is a good idea to take a multimeter and check them, preliminarily cleaned. If the resistance is equal to one, you will need to replace the part, because it is clearly defective.

Of course, the repair of the washing machine tank with your own hands is not an easy thing. To correctly disassemble, repair and most importantly, to correctly assemble the unit at home is almost a feat!

You can see the html codes in the text, fix it

Thank you so much, fixed it!

Hello. I have an Electrolux machine. Damaged the neck of the plastic tank where the water inlet hose goes in. A piece broke off from the neck and the hose is popping out. Decided to buy a new one, but I hate to throw it away, it's still good. Maybe there's a way to fix the neck. I would put the old machine in the summer kitchen and the new one in the house.