The washing machine frees women from time-consuming housework. Breakdown of the electromechanical device is a real disaster for the housewife.

The washing machine frees women from time-consuming housework. Breakdown of the electromechanical device is a real disaster for the housewife.

All clothes, linens have to be washed by hand. If the family is large, then every day you have to wash a whole mountain of clothes.

Today we will tell you what to do if the washing machine does not work, how with your own hands to adjust this miracle equipment.

Why the washing machine does not work

If the machine does not turn on when the buttons are pressed, the indicators are not lit, the reason for this may be:

- Lack of electricity in the socket due to a short circuit. In this case, the circuit breaker on the site can be knocked out, and the light, all appliances in the bathroom or kitchen, where the device stands, will be turned off.

- The socket is faulty. To check the socket, turn on any household appliance or a desk lamp. If the light in it lights up, then the socket is working, and you need to look for another reason for the non-working state of the machine. You can check the phases in the socket with an indicator screwdriver. If the other appliance does not turn on and the table lamp does not light up, then the contacts in the socket are loose.

De-energize the outlet, remove its housing, and look at the contacts. They should be copper in color, not gray, black or green. If the contacts are oxidized, they should be cleaned with sandpaper or an emery cloth.

If the contacts have holes through them, the socket must be replaced. Connect the wires firmly to the outlet. Secure the bare wires with electrical tape. Use a screwdriver to tighten the contacts. Screw in the set screws to prevent the outlet from wobbling.

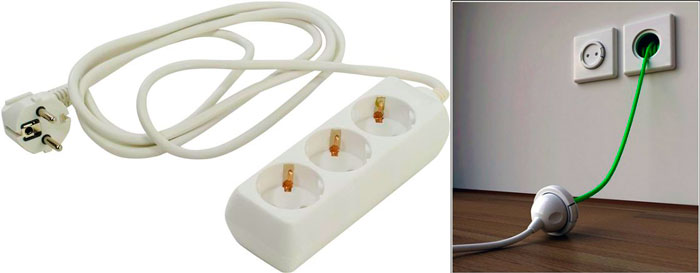

- The extension cord is defective. Replace the extension cord or plug the cord from the washer-dryer into the outlet.

- The power cord is defective. To check it, you need to run a multimeter along its length in some places. Sometimes you can clearly see that the cord is burnt and you can smell the smell of burning.

- The power button does not work.

The washing machine does not work if the power button is stuck. Put the multimeter in buzzer mode and test the button with the washing machine on and off. When the button is on, the multimeter should beep, when the device is off it should be silent.

- Failure of the noise filter.

The interference filter of the washing machine is necessary in order to extinguish the electromagnetic waves from the device. They negatively affect the radio, TV and computer, causing interference. In addition, it protects control box from power surges that can burn out the processor.

The interference filter of the washing machine is necessary in order to extinguish the electromagnetic waves from the device. They negatively affect the radio, TV and computer, causing interference. In addition, it protects control box from power surges that can burn out the processor.

The voltage from the mains goes to the interference filter, is normalized there, and then goes to the board. If the noise filter does not work, the electric current does not go further in the circuit, and the washing machine does not turn on.

To find out how the FPS works, remove the top cover and test its 3 wires: phase, zero, ground at the input and check the voltage at the output (2 wires: phase, zero).

- Control unit failure. To repair it, it is better to turn to professionals in the service center. But if you have an understanding of electronics, you can repair the board yourself.

The main element of the module is the condenser, as they say in popular parlance. In translation from the Latin "condensatus" means "condensed, compacted". It is a battery, which is able to give up all the charge in a fraction of a second. This is its peculiarity.

What to do if the washing machine stopped working because of the control module

- If the probe from a multimeter in contact with the capacitor will beep and show zero resistance, it means that there was a short circuit in it. The capacitors in the control module are not repaired, but replaced, using a soldering iron. Several filters are installed along with them to reduce the risk of failure of the new capacitor. They solder it to the positive electrode on the board.

- Often the modules burn out because of the resistors. First you need to test the module. The first order resistors have a resistance of 8 ohms, and the second order resistors no more than 10 ohms. The overload on the first order resistors should not exceed 2 A, on the second order resistors not more than 3-5 A. If the resistance is not ok, you need to re-solder them.

- If the capacitors are okay, you need to test all elements of the control unit. If the problem is with the thyristor unit, first you need to measure the negative resistance. It breaks down mainly because of overloads from the mains and impulse noise. If the unit works, but the filter of the thyristor unit burned out, it is necessary to strip the cathode. A new filter is soldered through the positive contact.

- Sometimes the trigger in the thyristor unit fails due to a capacitor malfunction. To find out if it is faulty or not, you need to test it on the output pins. The voltage should not be higher than 12 V. If it has failed, solder the output pins and replace the trigger.

The trigger is lit, but the program does not work. Causes

- The UBL - loading hatch interlock does not work. If there is voltage at the input, but the hatch does not lock, then the program does not start. To check if the part is working, you need to wire it.

There are 2 types of locks on the UBL:

Basically, the new generation of washing machines have thermal locks. The thermocouple is energized, under its influence it heats up, transferring heat to the bimetallic plate. It, in turn, bends from the heat and locks the door with a latch.

A signal is transmitted to the control unit to close the door, and the program begins to run.

When the wash is finished, the load the door does not open immediatelybecause by disconnecting the program from the thermal lock, the voltage is reduced and the bimetallic plate begins to cool. When it reaches a certain temperature, it returns to its shape, thereby pushing back the lock. The latch is released.

- If the thermo-lock is good, then you should check the other parts.

- If the boot door locking device hatch locking device does not work, then it must be replaced.

The bimetallic plate is destroyed by the constant temperature difference, which leads to the lock jamming. To repair the lock of the boot lid, you need to remove the clamp, and then the rubber collar, then on the sides of the lock unscrew the screws, take out the lock. Replace it with a new one: screw back two screws, put on the cuff and secure the clamp.

When the washer-dryer is switched on, the lights flash simultaneously or alternately

Cause: The internal wires of the appliance are damaged.

To fix the damage, you need to ring all wires and replace the damaged section of the wiring or call a specialist at home. You can take the machine to a service center.

The motor is defective

Sometimes the machine can pour water, start the program, but when washing there is noise, sparks. What is the problem? What has happened? The reason-breakage of the motor or a brush rubbed off.

Three types of motors are used in household washing appliances.

- Asynchronous. This type is used in old-style washing machines.

- Collector. The installation takes place in washing machines Indesit, Electrolux, Zanussi, Candy, Ariston.

- Inverter. This type of motor is mainly used in modern models of washing machines Samsung and Lg.

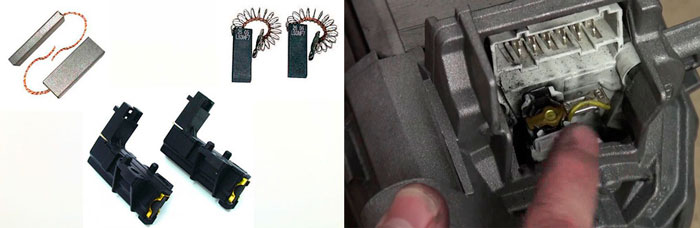

Collector motors do not work:

- due to wiping brushes. Brushes over time are reduced in size, which leads to incorrect operation of the motor;

- Because of lamellae. In case of a power surge, the lamellas peel off;

- because of the rotor and stator windings. A broken or shorted winding makes the motor impossible to operate.

Asynchronous motors are similar to collector motors. An inverter motor is a direct-drive motor. If it breaks down, the system sends a fault signal to the display, displaying an error code.

Replacing brushes

To replace the brush, the following steps are required:

- Remove the back wall. To do this, unscrew the bolts, remove the belt from the pulley and motor. On the motor, remove the fasteners and pull it toward you.

- Disconnect the wires.

- Remove the motor from the machine and inspect the brushes.

- If the brushes are worn out, replace them. To do this, unscrew the screws holding the brush and wire terminals. Reassemble the machine in reverse order.

Repairing the blades

You will be told of a faulty lamellae by the noise that appears when you rotate the rotor by hand. Visually inspect the lamellae and you will notice burrs, dents, and bumps that are caused by prolonged use of the washer and the brushes rubbing against the lamellae. The brushes rub against the lamellae, causing irregularities on them. The rotor or stator can also short out, causing the lamellae to peel off.

If the winding is burned out, the motor has to be replaced. the motor. It is impractical to replace the motor, because the part is expensive. It is better to buy a new washing machine.

Today we have disclosed the reasons why the electromechanical device does not turn on, as well as shared knowledge on what to do if the washing machine does not work. Listen to our advice, and your machine will work and please you for a long time.