If you have noticed by turning the switch that the centrifuge does not turn on in your semi-automatic machine, do not despair !

If you have noticed by turning the switch that the centrifuge does not turn on in your semi-automatic machine, do not despair !

Causes of a non-functioning centrifuge

There are Several causes that cause the problem:

- Damage to the safety sensor.

- Brake mechanism pads.

- Failure in the timer.

- Damage to the electrical winding.

- Other causes of malfunction.

Damaged safety sensor

Some models like Daewoo (Daewoo) or Saturn, there is a sensor on the door that closes the centrifuge tank. It is needed to disable the start-up. To get to it, you will need to remove the top panel of the washing machine - under it and there is a sensor with 2 contacts, which should be treated with absorbent cotton soaked in alcohol.Scratch contacts with a knife or clean them with sandpaper is not necessary. Then it is necessary to check the functioning of the sensor. The contacts should close when the cover is closed.

Some models like Daewoo (Daewoo) or Saturn, there is a sensor on the door that closes the centrifuge tank. It is needed to disable the start-up. To get to it, you will need to remove the top panel of the washing machine - under it and there is a sensor with 2 contacts, which should be treated with absorbent cotton soaked in alcohol.Scratch contacts with a knife or clean them with sandpaper is not necessary. Then it is necessary to check the functioning of the sensor. The contacts should close when the cover is closed.

Brake blocks

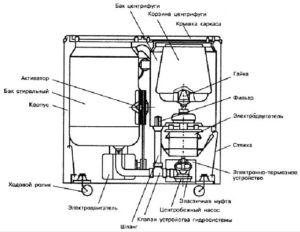

The brake shoes are installed under the centrifuge and thus brake it when it is opened.

The shoes are connected to the cover by a cable. When the cover is opened, the cable pulls on

the pads are around the part of the motor that is rotating. Thus, the centrifuge is stopped.

It is necessary to open the back of the SMP and check the tension of the cable so that the pads do not touch the motor when the door is closed, because touching the brake pads can prevent the electric motor from starting.

Fault in the timer

In most semi-automatic washing machines (SMPs), the timer is located under the top panel of the unit. It can be repaired by cleaning the contacts.

In most semi-automatic washing machines (SMPs), the timer is located under the top panel of the unit. It can be repaired by cleaning the contacts.

There are many tips on how to remove the panel, since washing machines are designed differently by different companies.

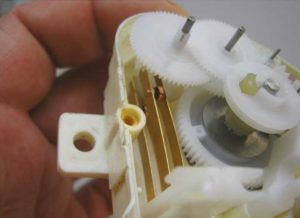

Once you remove the top panel, you will notice a device that resembles a clock with gears.

Inside this device there are contacts which may burn out if used for a long period of time. It is caused by soot, which does not allow any current flow.

Inside this device there are contacts which may burn out if used for a long period of time. It is caused by soot, which does not allow any current flow.

You have to be very careful when disassembling the timer, because the cover of this mechanism also serves to fix the gears on it. After loosening all the screws, you have to remove it so that the gear wheels don't fall out when you open it. If you are worried that you won't be able to open the cover gently, then it's better to be sure and take pictures of the whole mechanism. After removing the cover you will notice the pins. They need to be wiped with alcohol, just like in the sensor.

Damage to the electrical winding

This can be checked with a tester, that is, a measuring instrument. Here are three steps on how to do it.

First, find the ends of the wires that come out of the electric motor. There are usually three wires: the first is the common wire, the second is the one that leads to the starting winding, and the third leads to the operating winding. The common wire is usually marked with the letter "N" and made blue.

First, find the ends of the wires that come out of the electric motor. There are usually three wires: the first is the common wire, the second is the one that leads to the starting winding, and the third leads to the operating winding. The common wire is usually marked with the letter "N" and made blue.- It is necessary to set the resistance test on the device, and measure it between the common wire and one of the other two, for example - red. If the resistance reading on the screen is present, then there is nothing wrong with this winding.

Do the same with the other pair, with the common and, let's say, the white wire. Then we measure the resistance and note the readings of the device. If there is no resistance, it means that the winding is burned out. That is, the reason that the centrifuge does not work in your machine is a malfunction of the electric motor.

Do the same with the other pair, with the common and, let's say, the white wire. Then we measure the resistance and note the readings of the device. If there is no resistance, it means that the winding is burned out. That is, the reason that the centrifuge does not work in your machine is a malfunction of the electric motor.

In this case, there are two options: buy and install a new motor or send the old motor for rewinding.

Other causes of centrifuge failure in a semiautomatic machine

Let's take a look at The most common causes of malfunction in the spinning system.

The motor hums loudly, but the spin does not turn on . This means that the belt that connects the pulleys of the centrifuge and the motor has torn or come off.

The motor hums loudly, but the spin does not turn on . This means that the belt that connects the pulleys of the centrifuge and the motor has torn or come off.- If the machine is used for a long time, it is possible that the rubber bushing on the diaphragm may be worn. A large gap between the parts will prevent the spin from starting. To make the machine work, it is necessary to replace the bushing.

- If you have checked the electric motor and verified that it is in good working order, it may be It could be a faulty thermal relayor the step down transformer. These parts cannot be repaired and must be replaced with new ones.

- It's also a good idea to check if there are any small items wrapped around the motor shaft. They can fly out during spinning and get into the middle of the machine.

- Unevenly placed laundry in the middle of the centrifuge This may cause the centrifuge to wobble, preventing it from starting.

- If the activator spin motors are not working, it is a good idea to check the fuseThe fuse is located in the middle of the machine behind the rear panel. You can also check the electrical plug (contacts).

However, if you follow our tips carefully, carefully and without haste perform the necessary actions, you will be able to to repair your washing machine yourself. . your washing machine yourself, without any help. This is especially true for repairing the centrifuge in a semi-automatic washing machine.