One of the best helpers in the house-washer. It facilitates the work of a woman, frees her at least from laundry. If the family is large, then have to do laundry every day to keep the apartment clean and hygiene of its residents. Therefore, the breakdown of the washing machine is a real problem for women.

One of the best helpers in the house-washer. It facilitates the work of a woman, frees her at least from laundry. If the family is large, then have to do laundry every day to keep the apartment clean and hygiene of its residents. Therefore, the breakdown of the washing machine is a real problem for women.

All the laundry is a heavy burden on her shoulders. And all the clothes the housewife begins to wash by hand, wasting time and effort. Every day she wants a new washing machine or to repair the old one as soon as possible. But there is no money for repairs.

What do you do? You have to find a way out of the situation. If your husband with hands and head, he will be able to find the cause of the breakdown and replace the faulty part with a new one himself. Today we will tell you how to disassemble the washing machine Lg and any other model.

Tools for Disassembling a Washing Machine

Machine brands differ from each other by some features: washing programs, size, number of revolutions, but the principle of disassembling washing machines is the same.

For quality and fast disassembly are needed:

- two screwdrivers-small flat and Phillips for unscrewing the fasteners;

- round pliers or pliers;

- awl;

- hammer;

- impact wrenches and socket wrenches;

- pliers;

- pliers.

How to disassemble the Lg washing machine with your hands

The internal parts of the device are protected from negative influences of the environment by metal elements of the housing: back wall, front panel, top cover.

- Before you start disassembling the washing machine with your own hands, you must unplug the cord from the socket to de-energize it, to protect yourself from electric shock. Disconnect the cold and hot water supply.

- Unscrew the two screws at the top, then pull the top cover slightly toward you, lift it up, and remove it. The back of every Lg washing machine has a service hatch that's almost the size of the back wall. Therefore, to get to the parts of the device that are under it, the wall can not be removed, and unscrew the entire perimeter of the fasteners of the service hatch, remove it.

- Next, you need to remove the control panel, so as not to interfere with the disassembly of the unit. To do this, pull out the detergent container. Under it there are two screws, unscrew them with a Phillips screwdriver. Then take a flathead screwdriver and use it to pry open the top latches that hold the control panel in place and remove them. They will make a slight click. Then release the bottom latches until they click into place by pulling the panel toward you and lifting it up. The control box may not be removed completely, but can be pushed to the side panel and secured to it with tape.

- Remove the drum collar.. To do this, you need to open the door, press the clamp spring and pull it off. On the model of the washing machine Lg only the spring that holds the cuff, there are no clever snaps or teeth. Hide the rubber band far into the depths by removing it from the door.

- Open the hatch where the filter .. Bite off the bolts on the right and left side of the filter and remove the front bottom panel, which is called the trim panel. Now there is nothing in the way of removing the front panel: not the control panel, not the collar, not the door.

- Unscrew the bolts at the bottom and top of the front wall. On it is the hatch lock, which is connected to the rest of the machine. Slide your hand between the front panel of the unit. Through this gap we can reach the wire and pull it out. Another option is to unscrew the hatch lock from the front wall.

- How to disassemble the pump of the washing machine Lg

To do this, put the device on its side and remove the pump through the bottom, first disconnecting the wires from it. To pull out the drain pump, you need to unscrew the screws and disconnect the clamps. To do this, press on the latches with pliers and disconnect the drain hose and pipe.

To disassemble the pump you need to remove the screws on the volute. Clean the volute of dirt and slime.

Pay attention to the impeller, twist it on the shaft, if it rotates, if it has no damage. If it is broken, replace the impeller with a new one.

Also check the rubber gaskets. If the gasket is cracked or torn, replace it. Next, use a screwdriver to pry open the latch and remove the motor from the coil. Remove the monolithic cross member by heating it with a construction hair dryer. Then remove the magnet from the shaft.

After that, clean all the parts of the pump, remove the dirt, check the bearing. Lubricate the bearing. If broken, replace it. Start reassembling according to the picture you took before disassembling the drain pump.

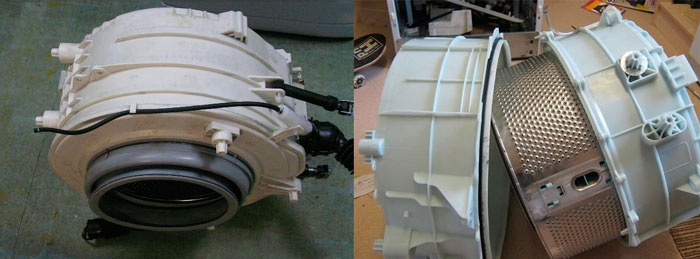

How to disassemble the loading tank of the Lg washing machine with direct drive

So, we have removed all the panels: the front, back and top cover, the control module. Now we will tell you how to disassemble the loading tank of Lg washing machine with direct drive.

This work in the service center is the most expensive, because the machine must be completely disassembled. The bearing and packing are in the back of the tank. To find out if the bearing is faulty or fine, rotate the drum by hand.

If you hear a creaking and rumbling, it means that the bearing is not working, it must be replaced.

As soon as you buy Lg, you should immediately set the washing machine on a flat surface, adjusting it on the level, so that the bearings are evenly loaded. If you see a leak in the back of the tank, then the gland has failed.

To get to the bearing, you need to completely disassemble the drum. Replace the part with a new one of this particular model. From other machines, you can not take a bearing, because it will not fit. When buying it in the store, pay attention to the integrity and quality of the part.

Direct drive, or Direct Drive-a new technology used by the Korean firm Lg. Thanks to it, the life of the washing machine is longer, because it does not have a drive belt.

The machine works quietly. In this brand of washer-dryer, the motor is located at the back of the loader, not at the bottom like in other units.

- To easily remove the drum, you must remove the counterweights. Unscrew the bolts at the upper counterweight, remove it, and do the same with the lower counterweight.

- At the top of the tank are the hoses. They need to be removed. Use a Phillips screwdriver to loosen the hose clamps. Loosen the clamps and disconnect the hoses from the tank.

- At the bottom of the tank you must also disconnect The thermistor .. Squeeze the connector's latch and remove it. Take a pair of wire cutters and cut the wire tie that connects the thermistor to the wires to the heater and grounding contact.

- The ground contact is secured with a 10" nut. Unscrew the contact with a 10 head.

- Disconnect all machine parts from the tank of the washing machine, as well as the wires of the heating element, drain pump, motor. Take out the terminals with which the sensors are connected to the loading tank and remove them.

- Disconnect the water level gauge and drain pump connection from the tank drain pump nozzleso that they do not interfere with the removal of the drum. To do this, use a Phillips screwdriver to unscrew the clamp that holds the branch on the tank. After loosening the clamp, disconnect the spigot from the tank. These spigots connect the loading tank to the rest of the unit.

- Remove the screws that secure the pressure chamber. Next, unscrew the nut tightening the rotor with a 16 head. You have to hold it, because the bolt is difficult to unscrew. If you are still unable to unscrew the bolt, ask someone to hold the drum inside.

- Remove the rotor. Underneath is the stator, which is bolted down with several bolts. Take a 10 head and unscrew each one.

- When you unscrew the last bolt, hold the stator so it doesn't fall off and get damaged. Remove the stator by lowering it down and tilting it. Disconnect the connector retainer and then the connector. Remove them from the stator. Now the tank and drum are not connected to anything, but are on the shock absorbers and springs.

- Now you have to remove the pins that hold and connect the shock absorbers. They have 2 locking tabs. Take a 13 head and put it on the pins so as to squeeze these tendrils. Then pull the pins out toward you with the pliers. The shock absorber can now be removed from the tank.

- Then remove the springs. They have a plug on them that keeps them from popping off the loading tank. Use a flathead screwdriver to pry the plug off, then remove the springs.

- Disconnect the hopper from the springs and place it with the pulley up. The motor is removed along with the tank.

- Unscrew the motor. Pull the tank out.

- Put it on the wooden blocks with the pulley up and use a 10 head to remove the bolts. Now one half can be lifted easily. Use a screwdriver to make it come apart faster. Inspect the top half of the tank to make sure there are no cracks or chips. If there are, the top half of the tank can be replaced. Try to pull the drum out of the other half of the tank. If it does not come out, turn the tank upside down and knock the drum out of the tank. There may be a bearing stuck in it and preventing the drum from coming out of the tank.

- To do this, place the inverted tank on wooden blocks with the plastic part to bang on the drum shaft. Before this action, pour some penetrating grease into the seating and let it soak for a while-1 minute.

- Take a block of wood and place it on the shaft so as not to damage it when tapping with the hammer. Hit the wood and the shaft with the hammer. The drum will pop out.

- Remove the other half of the drum. Examine the drum. If it's okay, put it aside, we don't need it yet.

- Turn the tank half over and use a flathead screwdriver to pry the gland from it.

- Remove the dirt. Then lubricate the edges of the bearing with penetrating grease over the seating area to make it easier to knock it out. Excess oil should then be removed so as not to weaken the tank material. Hit the bearing, the bottom one first, with a hammer. Then turn the tank over and knock out the other bearing from the back side.

- When the bearings are out, use a nylon or brass brush to brush the seat free of dirt. Do not use a metal brush for this purpose because it will damage the tank. Before putting the bearings in place, lubricate the edges with liquid soap to make them easier to install. Put the new bearings in place and settle them with a hammer.

We told you how to disassemble the load tank to replace the bearings and oil seals, how to take the drain pump out of the washing machine, disassemble it and clean it. Now you know how to repair the device so that you don't have to pay huge money for a complete disassembly of the machine and its restoration.

Ski 12 kg true steam , how to remove the engine (leaking)