Italian Candy washing machines are popular among consumers because of the good quality-price ratio. Despite the excellent performance and reliability, the machines sometimes break down. It always happens suddenly.

Italian Candy washing machines are popular among consumers because of the good quality-price ratio. Despite the excellent performance and reliability, the machines sometimes break down. It always happens suddenly.

But do not get too upset, most of the breakdowns can be solved independently. Specialists from the Kandi service center are sure that many errors occur due to improper handling.

Specialists from the Kandi service center are sure that many errors occur due to improper handling. By the way, I recommend contacting EuroBytService, if you need a really high-quality and fast repair of a washing machine of this brand.

Main problems

It is good, if the machine is equipped with the function of self-diagnosis. Then the built-in controller itself will determine what the problem is and report it with an alphanumeric code on the display.

- The machine won't turn on.

- В There is still water in the drum..

- Water does not heat up.

- No water draining or no water at all.

- Unclear noise is heard during operation. noise or a strong vibration can be heard during operation ..

- The electronic module is broken. With this problem, the machine will not work, even if it is included in the network, programs are not set, indicators are flashing chaotically.

The machine does not turn on

What should be done in this case?

Try pulling the plug out of the socket and inserting it again. You can now try turning on the power button.

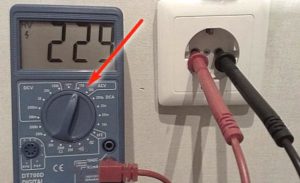

Try pulling the plug out of the socket and inserting it again. You can now try turning on the power button.- Didn't step 1 help? Maybe the outlet is not working? Try plugging another appliance into it.

- The cause of the malfunction may be oxidation of the contacts or a burnout in the mains button. You can check this with a tester. If the problem is detected, the part is replaced with a new one.

The water is not heated

The reason for the absence of warm or hot water during washing is due to a faulty heating element. In this case, the self-diagnostic function will inform the user of error E05 or blink the indicator 16 times after 5 seconds.

The reason for the absence of warm or hot water during washing is due to a faulty heating element. In this case, the self-diagnostic function will inform the user of error E05 or blink the indicator 16 times after 5 seconds.

There are many reasons for heating element failure. The most common are wear and tear or a thick layer of limescale on the the heating element Because of hard water.

How to check its performance and, if necessary, to carry out the repair of the washing machine candy your hands?

Removed the back wall of the washing machine.

Removed the back wall of the washing machine.- At the bottom you will see the heater shank with two wires.

- Using a multimeter, you need to determine the resistance of the device. If it is 20-30 ohms, it is in working order.

- If the heater is faulty, you need to take it out. To do this, unscrew the bolt between the wires, and the part is pulled out of the machine. The heating element may be stuck, then it is difficult to get it out without the help of a rubber hammer.

Installing a new heating element, the hole must first be cleaned from the layer of scale.

Installing a new heating element, the hole must first be cleaned from the layer of scale.- Check the efficiency of the heating element by turning the machine in heating mode.

Another reason for which water heating may not occur is a breakdown of the temperature sensor. In this case, the machine gives an error 05 or 5 blinks.

Failure of other parts in the washing machine

Faulty door

Broken Door lock device is indicated by code E01 or the indicator light flashes only once. The cause could be  electronics, then it is advisable to use professional help, or to try to repair the door of the washing machine candy yourself.

electronics, then it is advisable to use professional help, or to try to repair the door of the washing machine candy yourself.

To remove the lock you will need to remove the door seal. To do this, use a screwdriver to pick up the clamp that holds it. After removing the rubber band, unscrew the two screws that fasten the lock. The part is replaced, and the machine is assembled in reverse order.

The problem in the drain system

In this case, the machine can not drain the used water and displays the message E03 or blinks three times the indicators. What can be done?

Remove the bottom of the front panel.

Remove the bottom of the front panel.- Find the filter and by placing a low container, unscrew it counterclockwise.

- Clean and rinse under a pressure of water.

- The filter is attached to the tank with a nozzle. It should also be checked, as it is often clogged with various deposits. This can be done with a screwdriver. But be careful not to damage the pipe.

Now turn the machine on the drain mode and see if the pump impeller rotates. You will see it through the hole in the filter - it is a part with blades. Often hair, threads, wool are wrapped around the impeller. If it spins, the pump works. If it rotates, but the pump hums a lot and the impeller walks around, then the problem is in it and jams due to its looseness. Here already have to change the pump. Access to the pump of a Kandi washing machine is open through the bottom or tray, which is easily removed.

Now turn the machine on the drain mode and see if the pump impeller rotates. You will see it through the hole in the filter - it is a part with blades. Often hair, threads, wool are wrapped around the impeller. If it spins, the pump works. If it rotates, but the pump hums a lot and the impeller walks around, then the problem is in it and jams due to its looseness. Here already have to change the pump. Access to the pump of a Kandi washing machine is open through the bottom or tray, which is easily removed.

Fill hose Also requires cleaning. To do this, it is disconnected and cleaned with a cable with a cleaner.

It has an inlet filter, in which you often find sand and rust. The problem in this part is accompanied by the error E02 on the display or two blinking lights.

The pressostat under the top cover may malfunction.

The pressostat under the top cover may malfunction.

This sensor stops functioning if the tube attached to it is clogged.

After cleaning it of dirt, blow on it. If you hear a click, it means that the device is in working order.

Bearing failure

If the bearings are broken or worn, the machine in the process of operation emits a loud hum. To get to them in the washing machine candy, you will need to remove the top cover and pull out the tank. Kandy machines are compact, so the elements inside the equipment are arranged tightly to each other.

The algorithm of action is as follows:

Hoses are connected to the tank, which should all be disconnected.

Hoses are connected to the tank, which should all be disconnected.- Powder collector is pulled out.

- The counterweight is unscrewed.

- The belt is removed from the pulley of the drum.

- The wires are disconnected from the heating element.

- The motor is pulled out along the guide rails. Disconnect all wires coming from it beforehand.

The hatch is removed. To do this, the screws under the cuff are unscrewed, and the fixing collar is lifted with a screwdriver.

The hatch is removed. To do this, the screws under the cuff are unscrewed, and the fixing collar is lifted with a screwdriver.- The tank is disassembled into two parts.

- Remove the pulley from the drum shaft.

- Lightly tap out the bearing. Do not hit the shaft! A wooden bar is used for this purpose.

11. The drum bearing is also knocked out.

The new bearings are fitted in place of the old ones using a washer, nuts and rod.

The new bearings are fitted in place of the old ones using a washer, nuts and rod.

These instructions are for machines with a split tank. Some models have one-piece tanks, then the process is much more complicated and replacing the bearings at home is problematic.

Candy Aquamatic - error codes

Repair candy aquamatic washing machine is easier to make, as it is equipped with a self-diagnostic system. To decipher the error code, you need to pay attention to the left indicator. After reading the manual and knowing how many flashes are characteristic of a certain error code, you can make your own hands to repair the machine.

– Code 1 means that the hatch is blocked. In this case, you need to check whether the hatch is tightly closed. Also this code means a problem with the controller.

– Code 2 error of water supply to the tank - either not enough water or no water at all. Causes may be a valve, controller, water faucet, clogging.

– Code 3 indicates a problem with the drain. Perhaps the pump, drain hose, or filter and siphon are broken.

If there is water in the drum after the washing program, first shut off the water supply, remove the panel at the bottom of the housing and use the drain pump filter to drain the water. After that, you can deal with the problem. The pump is checked.

Thank you so much for your site! I and my husband were wondering why our machine broke - it was giving error 03, leaking, and wouldn't flush. It turned out to be a clogged filter. We used your instructions to unscrew and clean the filter. Now everything works

When Kandi turns on, it says: Hello, and that's it. The programs do not start. Please advise what to do